RE-INJECTO®

Re-Injectable injection hose for consecutive injection with Omnitek Inject micro fine cement or Gelacryl resins

Product Description

Black plastic injection hose with circular profile with an outside diameter of approx. 13 mm and an inner transport duct of approx. 7mm. The injection tube has micro slits to allow the injection material to exit the tube into the joint. The slits open with the injection pressure to allow injection grout to exit the tube and fill the joint. After injection, the slits will close again due to the reset force of the plastic closing the tube. The tube can be rinsed with water using a pressure of 1 bar

Field of application

Sealing cold and construction joints, pipe penetrations, joints between diaphragm walls and slabs through post-injection with Omnitek Inject micro fine cement or Gelacryl resin where consecutive re-injections are needed.

Application

Installation

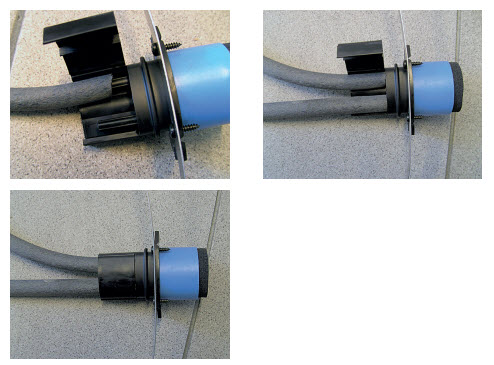

- Install the Twinbox to the outer reinforcement bars with the metal lashings taking into account the maximum tube length. One Twinbox needs to be provided per length of injection tube.

- Mount the Twinbox rubber pad flush with the formwork making contact with the formwork.

- Cut the injection tube to the required length. The max. length is 10 m.

- Re-injecto must be installed onto a flat concrete surface in continuous contact with the surface of the joint.

- Install Re-injecto in the middle of the joint. A concrete coverage of 7 cm to all sides is recommended. Make sure to have a good continuous contact with the joint surface

- Re-injecto is fixed to the concrete using clips. Apply 1 clip every 15 cm with a nail and washer.

- Open the clip at the back of the Twinbox and insert the tube ends onto the connector inside. Slide the tube ends all the way to the back of the Twinbox. The fit onto the tube connectors needs to be tight. Normal orientation is incoming tube right and outgoing tube left when facing the Twinbox from the rear

- Close the clip at the back of the Twinbox to secure the injection tube in place

- The ends of 2 consecutive Re-injecto tubes must be installed with a 15 cm overlap and 3-5 cm apart

Advantages

- Easy to re-inject using with Omnitek Inject or Gelacryl resins.

- Simple installation using the special Twinbox end piece connector.

- The Re-injecto hose can withstand concrete pressures of up to 20 meters.

- Re-injecto can be adapted on site to the exact length of the construction joint. The maximum length of the injection hose is 8 m for microfine cement injections and 10 m for resin injections.

- No special equipment required.

- The system allows injection under low pressure.

- Permanent seal after injection.

- No leak, no injection necessary.

- Can be bent without risk of closing up the tube.

- The profile prevents collapse of the tube through the weight of the concrete

Application

Injection

- De Neef Re-injecto can be injected and re-injected with Omnitek Inject micro fine cement or Gelacryl resins. Remark If required, Re-injecto can also be injected with De Neef polyurethane or epoxy grouts. Re-injection is however not possible with these types of resins.

- The injection should only take place when the concrete has completely cured and when all shrinkage and settlements have occurred (28 days).

- Visible cracks and deficiencies of the concrete surface should be closed with fast curing cement (Aquatek Plug) before injecting.

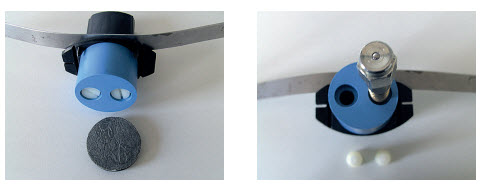

- Remove the foam pad from the Twinbox at both front and end of the injection length of Re-injecto.

- Remove the white sealing screw: - Right screw for outgoing. - Left screw for incoming

- Insert a conical packer into the correct injection opening of the Twinbox

- Test the permeability of the injection tube with water or compressed air.

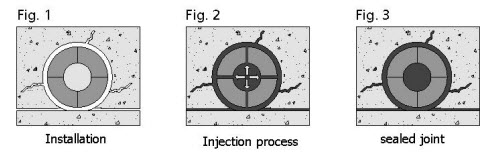

- Start the injection at low pressure to fill the injection tube. When the injection grout starts to pour cut of the open end piece at the other end, close the end injection port with a conical packer.

- Inject a quantity material into the injection hose. The flow of the material can be monitored through a pressure gauge mounted in front of the packer on the pump.

- Wait for half the curing time of the injection grout. Inject new injection material within the curing time of the injection grout until the pressure remains constant. When the pressure remains constant, the joint will no longer accept any injection grout and is sealed.

Re-Injection

- When there is a need for re-injection at a later stage, Re-injecto needs to be flushed with water to clear the hose.

- Remove the packer at the end of the injection tube.

- Connect a water pump or water hose to the injection packer. The rinsing pressure should be lower than 1.0 bars.

- Rinse the tube until clean water is expelled from the injection tube.

- The tube is now free for re-injection at a later date

Appearance

Charcoal grey round profiled injection tube with an inner duct and 4 micro slits on the circumference.

Consumption

The necessary quantities required depend on the length and layout of the various (construction) joints, which need to be sealed. The consumption of resin depends on the hollow voids around the Re-injecto, which need to be filled.

Packaging

Re-injecto is offered as a complete system

- Re-injecto tube : 100 m rolls.

- Twinbox : 10 pieces (10 pieces packaging)(*).

- Clips : 675 pieces (225 pieces packaging)(*).

(*) To be ordered separately

Storage

Unlimited in a dry place.

Technical data/properties

| Property | Value |

| Profile | Round |

| Material | Foamed PVC |

| Colour | Black |

| Outside diameter | 12,5 mm +/- 1 mm |

| Inside diameter | 7 mm +/- 1 mm |

| Length of slits | < 2,5 mm |

| Distance between slits | < 20 mm |

| Rinsing | < 1 bar |

| Opening pressure for slits | 4 bar or more 1 |

| Pressure to 30% distertion | 1 N/mm |

| Weight | > 85 g/m |

1 Depending on the viscosity of the injected material.

Accessories

To be ordered separately

- Packers and accessories

Health & Safety

For full information, contact the relevant Safety Data Sheet.

gcpat.com.br | North America customer service: 1-877-4AD-MIX (1-877-423-6491)

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

Re-Injecto is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc.

All rights reserved. GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140 USA.

Este documento está atualizado somente a partir da última data atualizada indicada abaixo e é válido apenas para uso no Brasil. É importante que você sempre consulte as informações atualmente disponíveis no URL abaixo para fornecer as informações mais atualizadas do produto no momento do uso. Literatura adicional, como Manuais do Empreiteiro, Boletins Técnicos, Desenhos detalhados e recomendações detalhadas, além de outros documentos relevantes, também estão disponíveis em www.gcpat.com.br. As informações encontradas em outros sites não devem ser consideradas, pois podem não estar atualizadas ou aplicáveis às condições em sua localização e não aceitamos qualquer responsabilidade pelo conteúdo delas. Se houver algum conflito ou se você precisar de mais informações, entre em contato com o Serviço de Atendimento ao Cliente do GCP.

Last Updated: 2025-05-13

https://gcpat.com.br/pt-br/solutions/products/de-neef-waterproofing-injection-solutions/re-injecto